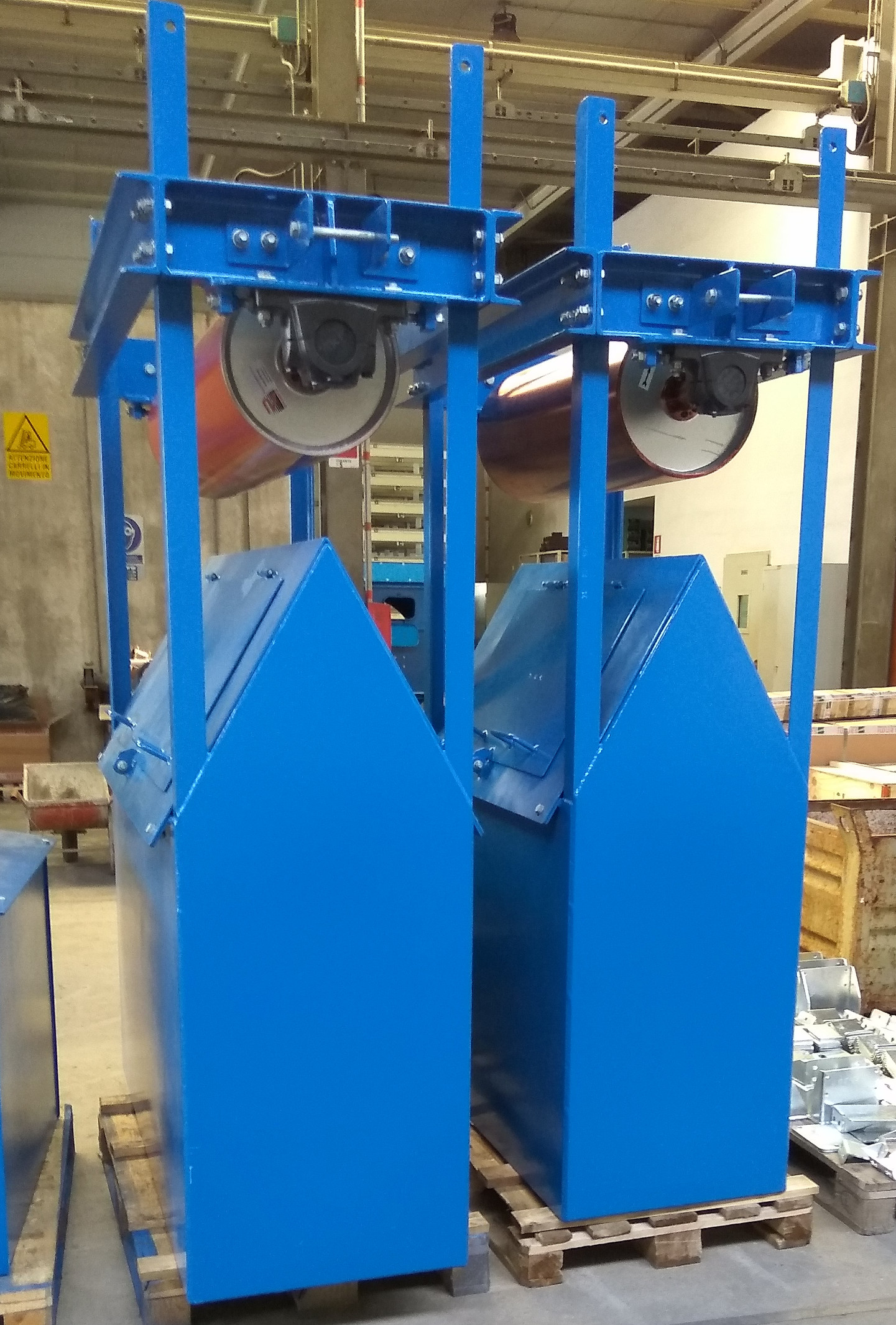

3101 – BPLK214 LOTOS COKING UNIT, HANDLING SYSTEM AND SCRAPER RECLAIMER

SOLUTION FOR BULK MATERIALS, STOCKYARD, STACKER, BELT CONVEYORS

Design, full supply (MEC-ELE-AUT) and commissioning of petcocke handling storage, reclaiming and truck loading system

JOB NUMBER

3101

SECTOR

OIL & GAS

END USER

LOTOS Asfalt Sp. z o.o.

LOCATION

POLAND

YEAR

2016-2017

CUSTOMER

KT KINETICS TECHNOLOGY S.p.a. (part of MAIRE TECNIMONT GROUP)

DETAILS

- conveyor capacity up to 200 tph

- plant scheduled to be commissioned on 2018

In the O&G market, an important recent project has been carried out by Sammi in Poland. After having acquired the commission by KT KINETICS TECHNOLOGY for Lotos EFRA project, in 2015, Sammi specialized team work started to design for the equipment required. The company has used all its know-how developed over the years to meet the needs of the customer.

The project concerns the manufacturing of the Coke Storage and Loading Facilities System, whose function is to handle the coke product from the Closed Coke Slurry System to the storage stockpile and then from this one to the truck loading station. The coke from the CCSS Unit is delivered to the storage bulk hall, where a shuttle conveyor allows for the distribution of material through building length. To prevent against dispersions of explosive Coke dusts, a loading bellows is provided under the shuttle.

From the stockpile, the coke is delivered to the truck loading system by means of a semi portal scraper that keep materials sending it to a conveyor chain up to truck loading station. In case of Reclaimer shutdown, petcoke can be routed directly to the truck loading station with a bypass route. Moreover, it is important to underline that all the systems are Atex certified for guarantee of security and suitable to working temperature from -25°C. The first level control system is performed by a fully redundant PLC.

All the steps of the project – that is not yet completed – have been followed by Sammi, from the beginning with the initial design to the following main phases, such as production, monitoring, final assembly. In accordance with the philosophy of the company “There are no barriers, only new challenges”, this recent contract is only a starting point for further international growth of Sammi.