2870 – CONVEYOR SYSTEM 250 t/h FOR CEMENT CRUSHING MILL FEEDING

SOLUTION FOR BULK MATERIALS, STOCKYARD, BELT CONVEYORS, SPILLAGE CHAIN, HOPPERS, EXTRACTEURS

Design, supply, erection, start up and commissioning of feeding system for coal mill. The aim of the project is to create storage areas for different products and extend the storage capacity up to 12,000m3. This installation meets the requirements of the Atex directives reducing dust emissions

JOB NUMBER

2870

SECTOR

CEMENT / POWER

END USER

CIMENTS CALCIA – Usine de Couvrot

LOCATION

FRANCE

YEAR

2011-2012

CUSTOMER

CIMENTS CALCIA

DETAILS

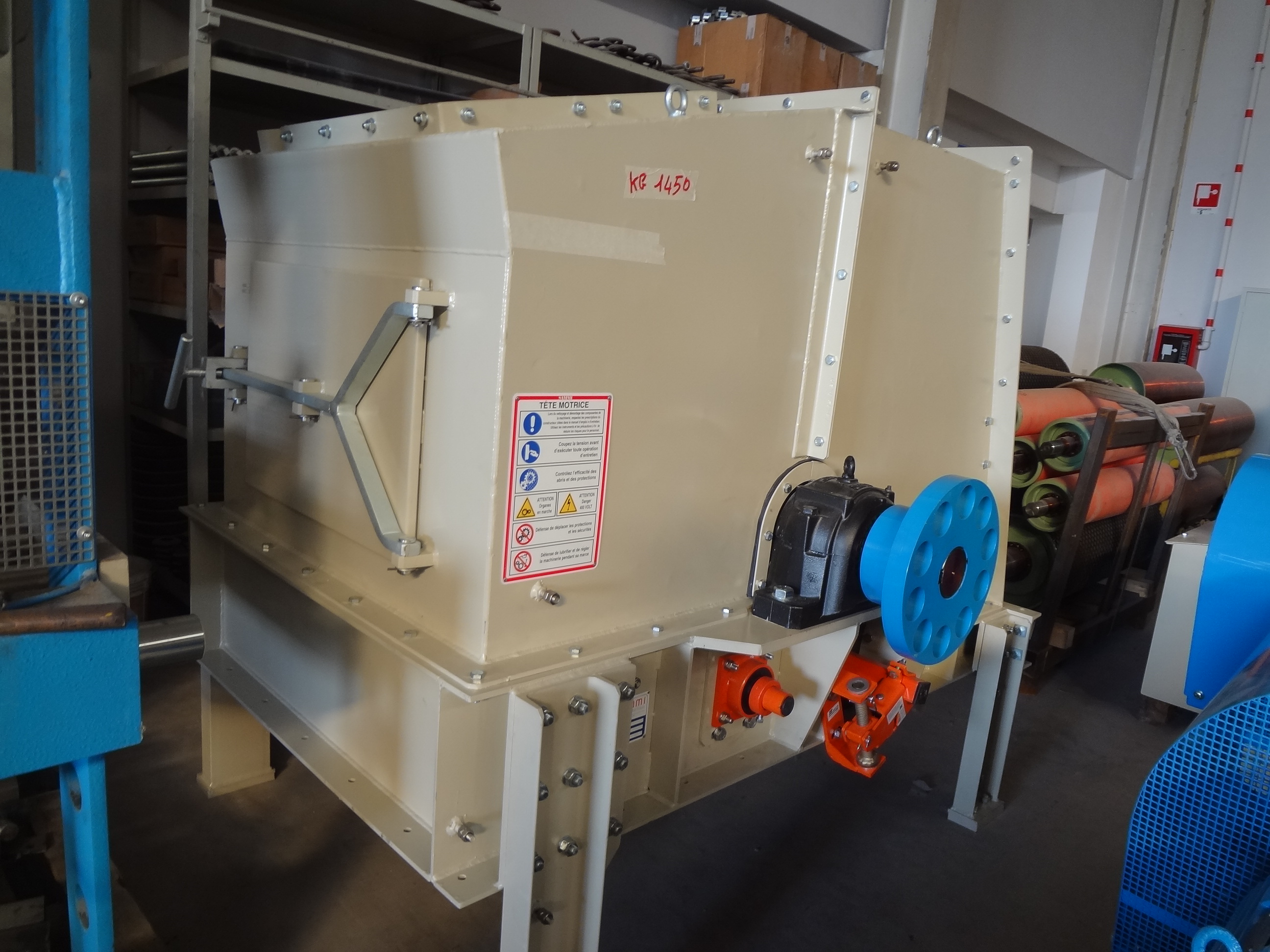

- belt conveyor capacity 250 tph

- material receiving, classification, sizing and transport to mill

Sammi is also committed on other projects. Among these, one of the most notable is the order awarded by the company on the end of 2011 for the complete design, supply, erection and commissioning services for a coal handling and storage system for Italcementi group (Ciment Calcia) to be installed in Couvrot, France.

The new installation can be divided in two main parts:

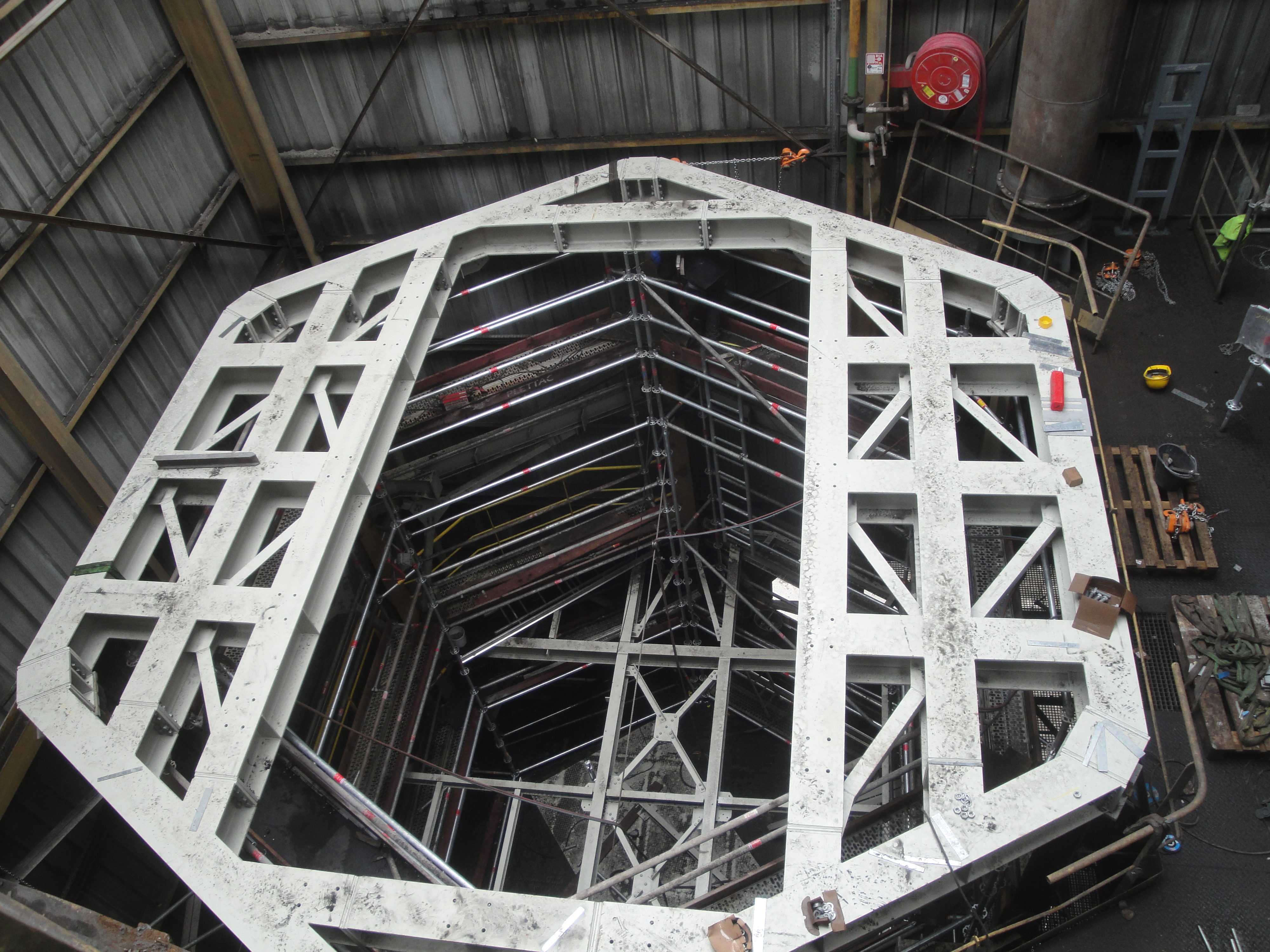

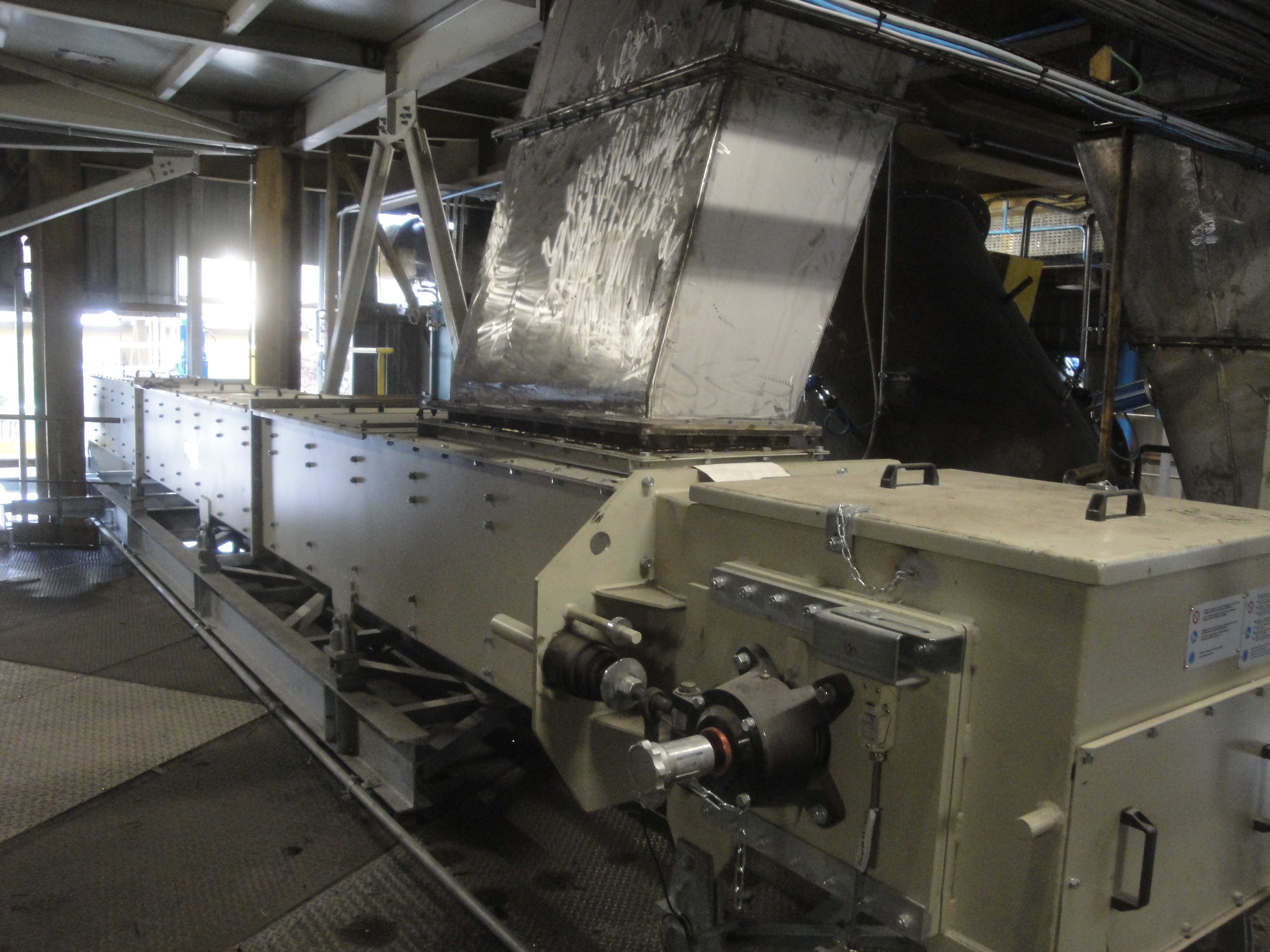

- coal storage facilities: which includes truck unloading station, receiving hopper, one 50m-long (250tph [tonnes per hour]) belt conveyor to transport the coal to a transfer and sieving station. From this station, coal can be either transported to a storage area or diverted to another conveyor if over-sized;

- coal recovery facilities: which includes one 250m-long belt conveyor with an altitude variation of 25m 100tph) to transport coal from storage to the existing crusher feeding facility which will be revamped with a new 110m3-capacity hopper and a set of Redler mass conveyor to feeds the crusher.

PROJECT FOCUS

DATA SHEET

Design, supply, erection, start up and commissioning of feeding system for coal mill