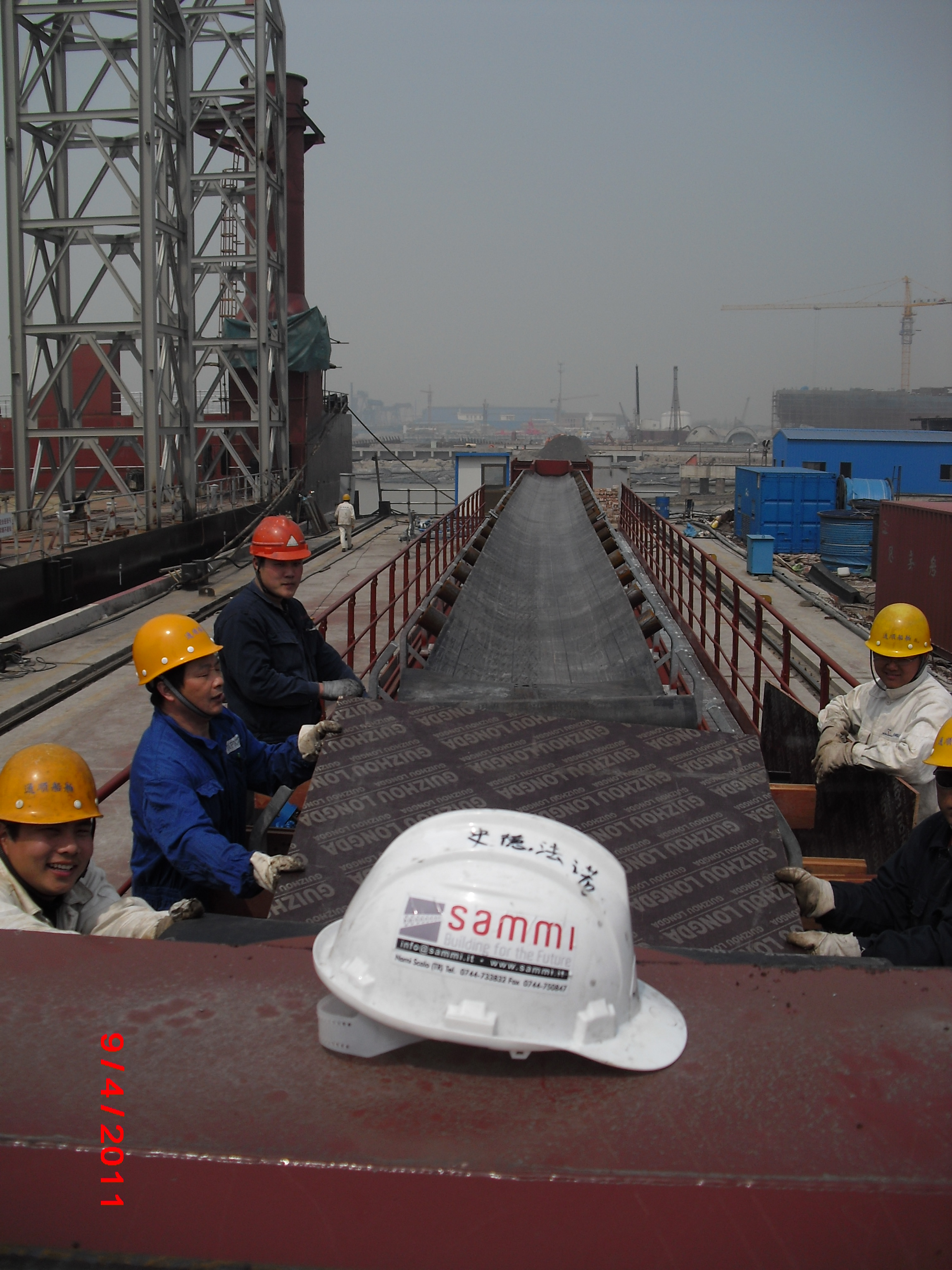

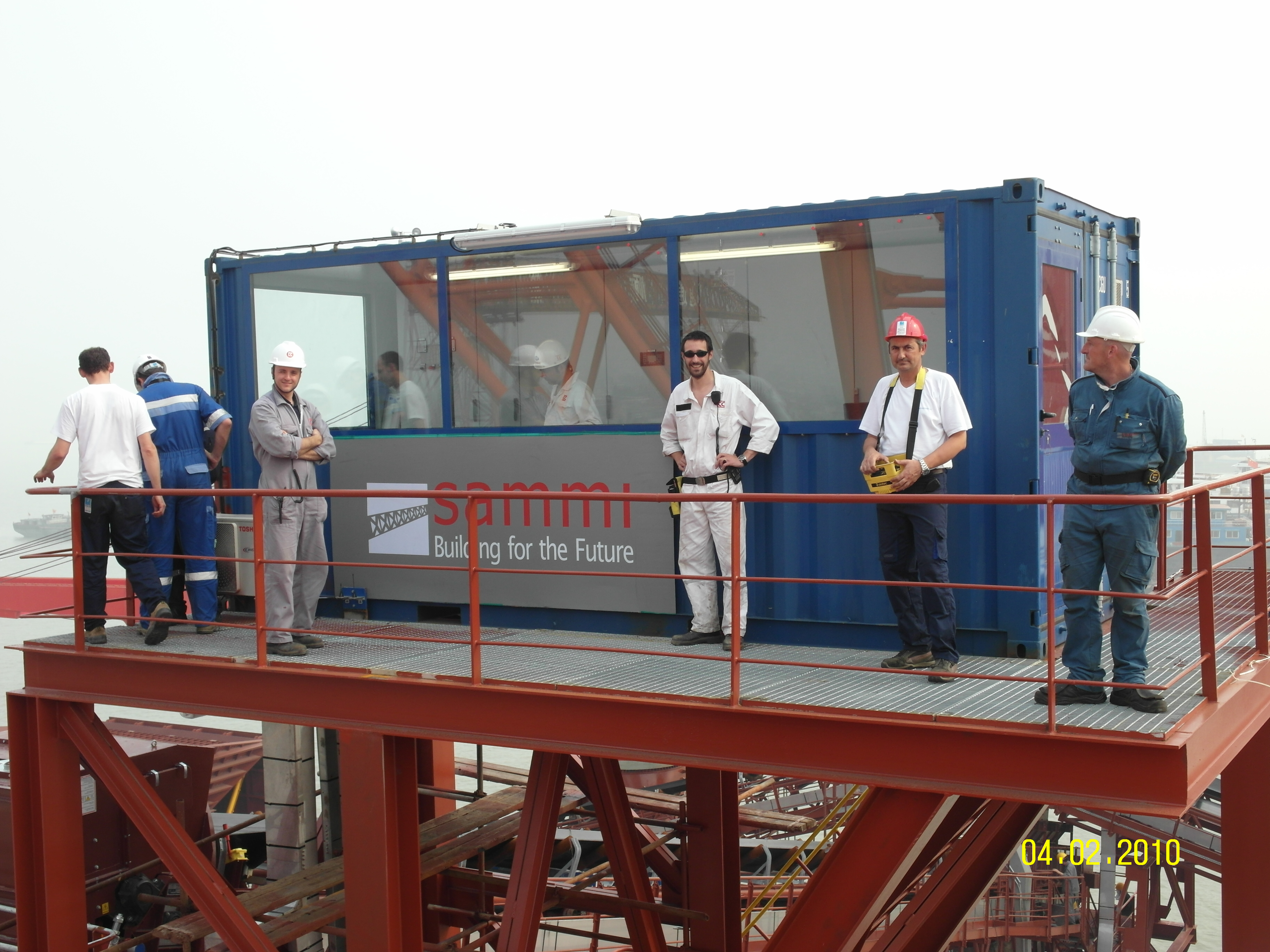

2767 – TRANSFER CONVEYOR SYSTEM OF RAW MATERIAL FOR TRANSHIPPER “BULK JAVA”

SOLUTION FOR BULK MATERIAL, EXTRACTORS, HOPPERS, SHIP LOADERS, BELT CONVEYORS

The plant concerns a new transfer conveyor system of raw material installed on new geared pontoon “Bulk Java” (the transhipper) for coal transport, capacity 2000t/h, capable of loading Cape Size from 180,000 DWT to 9 holds and Panamax from 80,000 DWT to 7 holds.

JOB NUMBER

2767

SECTOR

OFF-SHORE / POWER / PORT TERMINALS

END USER

BERAU MINING COAL

LOCATION

INDONESIA

YEAR

2010-2011

CUSTOMER

CAPO NOLI TRANSPORTES MARITIMOS LDA

DETAILS

The conveyor system is equipped with two shiploaders, one installed at fore and one at aft. When loading Ocean Going Vessels, the shiploaders have the chute axis distant 30 m from the centre of the foundation column and a jib inclination ranging from +12° to -10° (that can be controlled by means of hydraulic cylinders). The rotation speed at the top of the shiploader is abt. 10 m/min and the acceleration/deceleration time is 5 seconds.

The rotation is controlled by three hydraulic gearboxes fed by a hydraulic power pack. The equipment is provided with a hydraulic brake system, used while in operating conditions, and with a mechanical brake while in rest conditions (“service brake”). In operating conditions the rotation range of the shiploader is about -43° from the transversal position. The rotation of the shiploaders is limited by two magnetic limit switches (for each unit): the first generates an acoustic signal and a deceleration of the shiploader, the second stops the shiploader within the above mentioned braking time. The shiploader is installed on a high thickness steel column; the seat of the slewing bearing is placed on the top of this column.

The slewing bearing is provided with an internal teeth-range. The rotating part consists of a platform placed on top of the slewing bearing on which the support structure of the shiploader is installed. A hydraulic cylinder, manually calibrated, is provided for belt tensioning. While in rest position the shiploader is supported by two (2) rest saddles.